16

Years Experience

2021

2020

2019

2018

2017

Years Experience

Factory

Units/Month

R&D Researchers

Professors

PhD

Teaching Videos

Welding&Cutting Teachers

Workers

HSP: High Speed Pulse Transfer

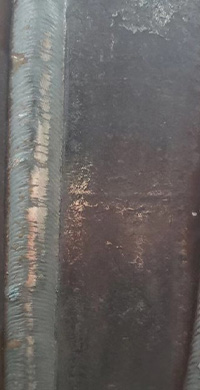

ULS: Ultra Low Spatters Control

HSS: High Speed Spot Arc

HPC: Hybrid Pulse Control

The new ULS process is a modified dip transfer arc with extremely high arc stability. The user can achieve high-quality weld seams with minimal spattering and an increased deposition rate, even in an intermediate and spray arc.

The new ULS process is a modified dip transfer arc with extremely high arc stability. The user can achieve high-quality weld seams with minimal spattering and an increased deposition rate, even in an intermediate and spray arc.

The new ULS process is a modified dip transfer arc with extremely high arc stability. The user can achieve high-quality weld seams with minimal spattering and an increased deposition rate, even in an intermediate and spray arc.

The new ULS process is a modified dip transfer arc with extremely high arc stability. The user can achieve high-quality weld seams with minimal spattering and an increased deposition rate, even in an intermediate and spray arc.

The new ULS process is a modified dip transfer arc with extremely high arc stability. The user can achieve high-quality weld seams with minimal spattering and an increased deposition rate, even in an intermediate and spray arc.

The new ULS process is a modified dip transfer arc with extremely high arc stability. The user can achieve high-quality weld seams with minimal spattering and an increased deposition rate, even in an intermediate and spray arc.

The new ULS process is a modified dip transfer arc with extremely high arc stability. The user can achieve high-quality weld seams with minimal spattering and an increased deposition rate, even in an intermediate and spray arc.

The new ULS process is a modified dip transfer arc with extremely high arc stability. The user can achieve high-quality weld seams with minimal spattering and an increased deposition rate, even in an intermediate and spray arc.

The new ULS process is a modified dip transfer arc with extremely high arc stability. The user can achieve high-quality weld seams with minimal spattering and an increased deposition rate, even in an intermediate and spray arc.

The new ULS process is a modified dip transfer arc with extremely high arc stability. The user can achieve high-quality weld seams with minimal spattering and an increased deposition rate, even in an intermediate and spray arc.

The new ULS process is a modified dip transfer arc with extremely high arc stability. The user can achieve high-quality weld seams with minimal spattering and an increased deposition rate, even in an intermediate and spray arc.

To be the welding & cutting expert.To be the world top brand.

To make welding & cutting more and more simple.

To make every welder & cutting lovers able to use toptechnologies.

To assemble a capable and well trained crew that is interestedand satisfied with their work and loyal to the company and totheir fellow employees.

To provide stable employment,good working conditions and thebest wage and benefit package that economic conditions allow.To maint ain our reputation for the finest quality products andthe best service available anywhere.

To earn a reasonable profit.